The metal casting business is consistently evolving, driven because of the demand for bigger precision, improved excellent, and diminished defects. In this landscape, the strain casting equipment performs a vital role. having said that, for one of the most demanding purposes, a specialized form of casting equipment is necessary: the vacuum force casting machine. this post explores the special advantages of these equipment, focusing on how they boost the precision and excellent of metal casting, specifically for treasured metals like gold and platinum.

Table of contents:

the benefits of applying Vacuum force Casting equipment for top-high-quality effects

How Vacuum stress Casting improves the Accuracy of Gold, Platinum, and also other Metals

Why Vacuum tension Casting is Essential for High-Precision Industries

some great benefits of utilizing Vacuum tension Casting devices for High-Quality benefits

Vacuum tension casting equipment give a substantial breakthrough in comparison with traditional casting strategies. The core benefit lies while in the elimination of air pockets and gas porosity in the casting. By executing the casting method below a vacuum, the molten steel is permitted to flow much more freely and completely fill the mold cavity. This brings about denser, much better castings with much less interior defects. On top of that, the application of force through the solidification stage helps you to additional consolidate the metallic, reducing shrinkage and increasing the general good quality. This can make vacuum stress casting perfect for generating intricate and sophisticated styles where by even the smallest imperfections can compromise the functionality or aesthetic attractiveness of the final item.

How Vacuum strain Casting improves the Accuracy of Gold, Platinum, as well as other Metals

The large price and exceptional Homes of cherished metals like gold and platinum necessitate Extraordinary casting precision. Vacuum gold casting device engineering is specifically meant to fulfill these demanding requirements. The vacuum surroundings don't just helps prevent oxidation with the molten metallic but will also assures a clean and constant casting method. This is especially significant for gold, which can certainly tarnish or produce area defects if subjected to air in the course of casting. Furthermore, the controlled tension used for the duration of solidification promotes uniform grain construction and minimizes the risk of cracking or distortion. This ends in castings that are dimensionally accurate, possess superb surface area end, and keep the specified mechanical Attributes.

Why Vacuum tension Casting is important for large-Precision pressure casting machine Industries

significant-precision industries, including aerospace, professional medical machine manufacturing, and substantial-close jewellery generation, depend on vacuum pressure casting to realize the stringent top quality criteria essential for his or her programs. The ability to create castings with tight tolerances, minimal defects, and constant materials Houses is paramount in these sectors. one example is, inside the aerospace sector, vacuum strain Forged elements are Employed in critical engine parts exactly where trustworthiness and performance are non-negotiable. likewise, in professional medical product manufacturing, vacuum stress casting guarantees the biocompatibility and structural integrity of implants. the advantages prolong to jewellery building in addition, where intricate layouts and flawless finishes are important for generating substantial-value items. finally, vacuum strain casting presents the mandatory Handle and precision to satisfy the demanding prerequisites of these industries. As evidenced by merchandise such as the TAKJ-VC-W accessible at https://taeantech.com/products/takj-vc-w, these machines are particularly made to cater into the precision necessary by vacuum force casting procedures.

In summary, vacuum pressure casting machines are indispensable resources for obtaining large precision and exceptional top quality in steel casting. The mix of vacuum surroundings and managed stress eradicates typical casting defects, boosts product Attributes, and makes certain dimensional precision. For industries demanding the very best levels of overall performance and dependability, investing in vacuum stress casting technologies is not merely a preference but a requirement. Consider the unique necessities within your software and examine the various vacuum tension casting alternatives available to unlock new possibilities in steel casting and elevate the standard of your last merchandise.

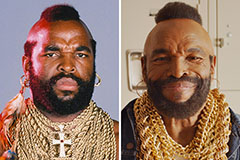

Mr. T Then & Now!

Mr. T Then & Now! Melissa Joan Hart Then & Now!

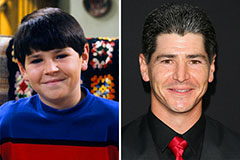

Melissa Joan Hart Then & Now! Michael Fishman Then & Now!

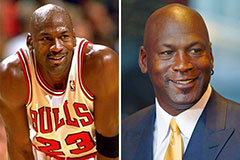

Michael Fishman Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now!